Asia

EMEA

LANXESS Canada Contacts

Contact our Sites in Canada

Media Inquiries

General Inquiries

Please click here to e-mail LANXESS Canada with product inquiries and general requests.

Global Press Releases

2018-04-16

LANXESS Liquid Purification Technologies at IFAT, May 14 to 18, 2018, Munich, Hall A2, Stand 215

Ion exchange and reverse osmosis: a perfect combination

With 80 years of experience in water treatment and purification, the specialty chemicals company LANXESS with its Liquid Purification Technologies business unit (LPT) has a solid basis to appear at this year’s IFAT. The world’s leading trade fair for water, sewage, waste, and raw materials management takes place in Munich on May 14-18, 2018. LPT is the only supplier in Europe to produce a wide range of ion exchange resins and adsorbents as well as membrane elements for reverse osmosis.

The combination of the two methods paves the way for highly efficient solutions. “Many years of experience with numerous reference projects together with our high-quality products from the Lewatit, Lewabrane, and Bayoxide ranges are the foundation for our success. Our customers worldwide benefit from this in various types of applications,” says Jean-Marc Vesselle, head of the LPT business unit.

Responses to global challenges

The reliable supply of drinking water to the world’s population is not the only challenge that constantly calls for new, innovative types of solutions. Water management in industry and agriculture also involves considerable challenges. Intelligent technologies and tailored products can help in the development of sustainable solutions. “Efficient processing and recycling methods will be essential in order to meet the demand for water in the future,” Vesselle states. LPT offers various services in this regard.

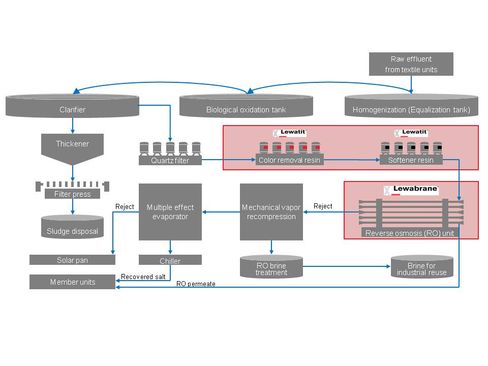

Dr. Jens Lipnizki, head of Technical Marketing Membrane at LPT, will discuss the example of efficient wastewater treatment resulting in the almost complete avoidance of wastewater at an Indian textile dyeing factory (minimal liquid discharge, MLD) as part of a presentation at a joint event by the German Water Partnership (GWP) and the Federal Ministry for Environment, Nature Conservation and Nuclear Safety (BMU) on May 15, 2018. His presentation as part of the India country special (IFAT forum B2), “Successful water management in India – challenges and opportunities”, illustrates how practical, sustainable solutions can be developed based on expertise and experience.

Performance times two

Numerous examples from the municipal and industrial sector show how ion exchange resins (IX) and reverse osmosis (RO) membranes complement one another to achieve optimal results in water treatment. As such, ion exchange resins can be installed in front of an RO unit, such as to remove organic impurities through adsorption, which would otherwise enable fouling on the membranes. Previous partial softening of the feed water with weak acidic ion exchange resin can also reduce both scaling on the membrane elements and the salt content of the feed with practically stoichiometric application of the regeneration agent. This enables more efficient operation of the RO plant. This procedure is recommended for highly carbonated, industrial process water.

Tailored ion exchange resins

A particular strength of ion exchange resins is their ability to selectively remove heavy metal cations or complex anions during the water purification process. Accordingly, LPT will present Lewatit TP106 at IFAT, which binds oxyanions such as perchlorate, chlorate, bromate, and nitrate with high selectivity.

It thus complements a series of special ion exchange resins, including Lewatit TP 107 and Lewatit TP 207. The former, a strong basic, macroporous resin based on an interlaced polyacrylate, enables the efficient removal of various types of polyatomic oxyanions. Notable is the high capacity for chromate, as well as vanadate and molybdate, during the treatment of drinking water. Similar to Lewatit TP 106, it is certified according to NSF/ANSI standard 61.

The weak acidic, monodisperse chelating resin Lewatit TP 207 exhibits high selectivity for bivalent heavy-metal ions in a neutral solution. It can be used to selectively remove copper ions, as well as lead, nickel, or zinc, for example, even in the presence of complexing amines, polyvalent carboxylic acids, or phosphates. With its Bayoxide product line, LPT also offers iron oxide adsorbents specially developed for the separation of arsenate and phosphate.

Also worth mentioning is another new product which will be presented at IFAT – the gel-like, strong basic Lewatit S 5128. This acrylate-divinylbenzene-copolymer enables highly effective adsorption and desorption of naturally occurring organic substances and is approved for use in food applications.

Energy-efficient membrane elements

Membrane elements from the Lewabrane RO ULP (Reverse Osmosis – Ultra-Low Pressure) series are the new high-end standard with regards to energy efficiency. They are designed for a test pressure of just 7.6 bar. Compared with standard elements, a 40 percent reduction in operating pressure is therefore sufficient. Energy and operating costs are reduced accordingly. “A membrane with high water permeability and high flow rates, like the one we offer with Lewabrane RO ULP, also helps to sustainably reduce investment costs for water purification,” highlights Alexander Scheffler, responsible for marketing in the LPT business unit.

The ULP membrane has the highest surface hydrophilicity of all Lewabrane types. A thin, protective water film on the surface of the membrane therefore prevents the adsorption of organic substances, or organic fouling. The ASD feed spacers used in the elements, which create more space for the flowing water between the membrane surfaces, also reduce fouling.

LewaPlus 2.0 – user-friendly IX and RO design

All findings from own research and development work and the experience from numerous reference projects throughout the world are continuously implemented in the LewaPlus design software, which is constantly developed by LPT. This makes it the perfect tool, especially for the design of combined reverse osmosis/ion exchange systems for water purification. Visitors to IFAT can experience the recently released and even more user-friendly version LewaPlus 2.0 in action.

LPT offers a comprehensive range of tailored ion exchange resins and RO membrane elements for various types of applications. For detailed information, visit http://lpt.lanxess.com.

Forward-Looking Statements

This company release contains certain forward-looking statements, including assumptions, opinions, expectations and views of the company or cited from third party sources. Various known and unknown risks, uncertainties and other factors could cause the actual results, financial position, development or performance of LANXESS AG to differ materially from the estimations expressed or implied herein. LANXESS AG does not guarantee that the assumptions underlying such forward-looking statements are free from errors nor does it accept any responsibility for the future accuracy of the opinions expressed in this presentation or the actual occurrence of the forecast developments. No representation or warranty (expressed or implied) is made as to, and no reliance should be placed on, any information, estimates, targets and opinions, contained herein, and no liability whatsoever is accepted as to any errors, omissions or misstatements contained herein, and accordingly, no representative of LANXESS AG or any of its affiliated companies or any of such person's officers, directors or employees accept any liability whatsoever arising directly or indirectly from the use of this document.

LANXESS is a leading specialty chemicals company with sales of EUR 9.7 billion in 2017 and about 19,200 employees in 25 countries. The company is currently represented at 74 production sites worldwide. The core business of LANXESS is the development, manufacturing and marketing of chemical intermediates, additives, specialty chemicals and plastics. Through ARLANXEO, the joint venture with Saudi Aramco, LANXESS is also a leading supplier of synthetic rubber. LANXESS is listed in the leading sustainability indices Dow Jones Sustainability Index (DJSI World and Europe) and FTSE4Good.

- Gallery