Asia

EMEA

LANXESS Canada Contacts

Contact our Sites in Canada

Media Inquiries

General Inquiries

Please click here to e-mail LANXESS Canada with product inquiries and general requests.

Global Press Releases

2018-04-24

LANXESS at Chinaplas 2018, April 24 – 27, 2018, Hall 7.2/Stand T31, National Exhibition and Convention Center, Hongqiao, Shanghai

Quality shapes future: Innovative plastic solutions at Chinaplas 2018

- High-tech engineering plastics

- Vehicle lightweight solutions

- Additives with safety and stability

Specialty chemicals company LANXESS exhibits at Chinaplas 2018 in Shanghai under the motto “Quality Shapes Future”. At stand T31, extending over 120 square meters in Hall 7.2, the company is presenting its latest developments in materials, processes and technologies for premium plastics solutions. Also on display are high-performance additives and color pigments developed for the polymer industry.

“The theme of the exhibition reflects LANXESS’s brand claim of ‘Quality Works’. In short, it means we aim to provide customers with high-performance products, to jointly develop innovation and sustainable application with them and to drive the industry value chain. We present environmentally friendly and energy-saving manufacturing processes, the latest technologies and solutions to the visitors of Chinaplas. The focus is on key industry trends such as electric cars, environmentally friendly buildings and building security,” says Ming Cheng Chien, CEO of LANXESS Greater China.

Focus on New Mobility

With the rapid development of new forms of mobility such as autonomous driving, the electrification of vehicle power trains, and new logistics concepts, LANXESS sees a wide application potential of high-tech thermoplastic materials. To meet the growing demands of the market, LANXESS announced in late 2017 that it is building a new high-performance engineering plastics compounding facility in Changzhou, China.

“LANXESS sees significant potential for the application of its high-tech plastics in lightweight design, charging systems, battery solutions, sensors for autonomous driving and housings of electric motors as well as in the infrastructures of e-mobility, for instance, in charging stations. We have developed dedicated and innovative solutions with our PA6, PA66 and PBT polyamides to tackle the challenges and innovate for e-mobility and autonomous driving,” says Michael Rockel, Head of Greater China Sales & Marketing of LANXESS’s High Performance Materials business unit.

Another hot topic at LANXESS is the new heat stabilization system called XTS2 (Extreme Temperature Stabilization). It increases the thermal stability of polyamide 66 to up to 230 °C. Important mechanical properties – such as tensile modulus, breaking stress or IZOD impact strength – are maintained at a high level even at constant temperatures of up to 230 °C. XTS2 materials have their target applications in vehicles with efficient combustion engines. The first product from the XTS2 portfolio is a polyamide 66 reinforced by 35 percent glass fiber, which is marketed as Durethan AKV35 XTS2. It is ideal for the production of components such as air intake manifolds with an integrated intercooler. Another polyamide 66 with a 30 percent glass fiber reinforcement is under development, which is used for blow molded hollow components such as air ducts in the engine compartment. The high temperature stabilization is also available for PA6 based materials, which are more cost efficient compared to PA66 based compounds.

Environmentally friendly lightweight solutions for the automotive industry

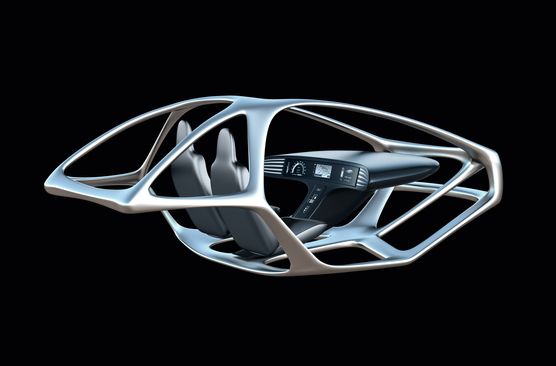

Depending on the requirements for the application in question, engineering plastics can entirely replace comparatively heavy metal parts or be combined with composite materials (such as the LANXESS Tepex product range). The weight of individual components can be reduced by using lightweight materials and technologies, without compromising on their physical properties, such as mechanical strength.

As one of many examples of lightweight applications, LANXESS will be exhibiting an oil pan module made of Durethan BKV 30 H2.0 (PA 6) for the Porsche 911 Carrera. This is a highly sophisticated component satisfying all the specific requirements imposed on the new-generation engine in terms of weight reduction, function integration and cost-efficient production and despite the industry standard is now designed in PA6 and not the traditional PA66 material.

At this exhibition, another focal topic of the LANXESS presence lies in the continuous-fiber-reinforced thermoplastic composites of the Tepex brand family. They are becoming increasingly important for lightweight vehicle design and can be found today in an increasing number of series production applications – for example, front-end mountings, underfloor protection and bumper beams, brake pedals, through-loading systems, and fuel tank reinforcements. There are also significant potentials for use in vehicle underbodies, for the protection of batteries and in new concepts for highly-integrated, multi-position seats. LANXESS is currently developing composite variants with electromagnetic shielding properties, especially for components of electrified vehicle drivetrains.

Tepex can also be used to fabricate virtually indestructible engine compartment trim, fuel tank covers and center tunnel covers, like those already in use in several standard models, such as the Bentley Bentayga SUV. These composites likewise are suitable for manufacturing very stiff, strong, thin-walled components, such as device mounts with high functional integration, versions of which are already in use in several standard models.

Products for sports equipment, such as soccer shoes, ski boots, bicycle parts and golf club components, are displayed as well. They likewise benefit from the significant weight advantages of this modern lightweight material.

Additives with safety and stability

As one of the world’s leading suppliers of flame retardant additives, LANXESS offers the plastics industry a comprehensive range of products. “The development trend of energy-efficient buildings promotes the rising demands for flame retardants. In the mid-term we expect that an annual average growth rate of 4 percent will be achieved in the market of flame-retardant additives,” says Hak Leong Chok, Executive Vice President of LANXESS Additives business unit, Asia Pacific. LANXESS provides customers with series of complementary bromine and phosphorus-based products from a single source. With outstanding performance, these materials are widely used in various fields of construction industry. “For our customers in China and other Asian countries, we offer tailor-made solutions and value-added services with technical competence centers such as in Nanjing and Qingdao.”

Emerald Innovation TM 3000, a sustainable flame retardant displayed at this exhibition, is based on a technology licensed from the Dow Chemical Corporation. It is mainly used for organic insulation material EPS (expanded polystyrene foam) and XPS (extruded polystyrene rigid foam) in construction industry. This product helps LANXESS’s customers to switch to more sustainable flame retardants. Due to the global commitment from foam producers to eliminate HBCD use by 2021 at the latest, LANXESS is thus supporting its customers’ necessary conversion and certification activities at an early stage with a sufficient range of alternative flame retardants as well as with customer-specific technical support.

In addition, LANXESS is also exhibiting its halogen-free phosphorous flame retardant and hydrolysis stabilizers. Levagard TP LXS 51114 is a low-emission flame retardant that is excellently suited to use in polyether and polyester polyurethane (PU) flexible foams, e.g. in automotive interiors. The product can also serve as a flame-retardant plasticizer in cellulose derivatives, particularly cellulose triacetate (CTA), showing great value in manufacturing housings for electronic devices. The halogen-free phosphoric acid ester Disflamoll 51092 has a low odor and can be used in many plastics, e.g. plasticized PVC, flexible PU foams, TPU, PC-ABS and NBR-PVC blends.

Stabaxol P 110, a hydrolysis stabilizer for plastics and polyurethanes, is the first product in a new line of innovative, low-emission polymeric carbodiimides based on alternative raw materials. It shows outstanding performance when used in the thermoplastics PET and in thermoplastic elastomers (TPE-E). Above all, in the bioplastic polylactic acid, it significantly extends the service life of the final article under moist and warm operating conditions.

Bringing color to the world of polymers

The demands on pigments for coloring plastics are high. Given the short dwell time and relatively low shear force in customer processes, they must display good dispersibility, i.e. they must be easy to disperse so as to reach their final tinting strength quickly. They must display high thermal stability, no migration and sufficient levels of light fastness and weather fastness for the intended application.

Colortherm iron and chromium oxide pigments from LANXESS meet these requirements in full. What’s more, they are easy to process and their special micronization allows for high throughput, because the very finely ground pigments disperse quickly in a plastic. The U.S. Food and Drug Administration (FDA) has recognized the environmental-friendly and safe pigments from the Colortherm range as a raw material for coloring toys and food packaging.

LANXESS has always been committed to environmental responsibility, efficiency and quality. For example, the Ningbo site, where the company produces inorganic pigments, was recently included in the list of environmentally friendly production facilities of the Chinese Ministry of Industry and Information Technology. With the developed “Ningbo process”, energy consumption in the production of iron oxide red pigments can be reduced by 80 percent and the by-products can be recycled.

Forward-Looking Statements

This company release contains certain forward-looking statements, including assumptions, opinions, expectations and views of the company or cited from third party sources. Various known and unknown risks, uncertainties and other factors could cause the actual results, financial position, development or performance of LANXESS AG to differ materially from the estimations expressed or implied herein. LANXESS AG does not guarantee that the assumptions underlying such forward-looking statements are free from errors nor does it accept any responsibility for the future accuracy of the opinions expressed in this presentation or the actual occurrence of the forecast developments. No representation or warranty (expressed or implied) is made as to, and no reliance should be placed on, any information, estimates, targets and opinions, contained herein, and no liability whatsoever is accepted as to any errors, omissions or misstatements contained herein, and accordingly, no representative of LANXESS AG or any of its affiliated companies or any of such person's officers, directors or employees accept any liability whatsoever arising directly or indirectly from the use of this document.

LANXESS is a leading specialty chemicals company with sales of EUR 9.7 billion in 2017 and about 19,200 employees in 25 countries. The company is currently represented at 74 production sites worldwide. The core business of LANXESS is the development, manufacturing and marketing of chemical intermediates, additives, specialty chemicals and plastics. Through ARLANXEO, the joint venture with Saudi Aramco, LANXESS is also a leading supplier of synthetic rubber. LANXESS is listed in the leading sustainability indices Dow Jones Sustainability Index (DJSI World and Europe) and FTSE4Good.

- Gallery