Asia

EMEA

LANXESS Canada Contacts

Contact our Sites in Canada

Media Inquiries

General Inquiries

Please click here to e-mail LANXESS Canada with product inquiries and general requests.

Global Press Releases

2016-10-19

LANXESS markets new polyamide 6 for engine oil pans

Extremely tough – even at low temperatures

- Rubber modification increases notch impact resistance

- Good stiffness and strength

- Meets OEM specifications

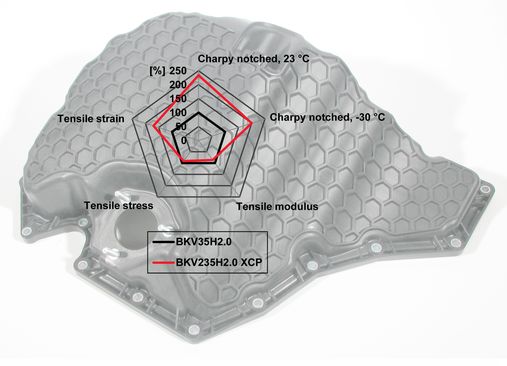

Passenger vehicles frequently are equipped with engine oil pans made of plastic. They incorporate the oil sump and, by nature of their function, are located at the lowest point of the oil circuit, meaning right above the road. LANXESS developed Durethan BKV 235 H2.0 XCP specifically for oil pans that have to offer high resistance to stone impact and the underbody hitting the ground, and that are not otherwise protected by sheet metal or other cover materials. The polyamide is rubber-modified and reinforced with 35 percent special short glass fibers. The abbreviation XCP stands for Extreme Crash Performance and therefore also for the material’s high toughness. “Our structural material is characterized by outstanding Charpy notch impact resistance at low temperatures. Although it contains a rubber-based toughness modifier, its stiffness and strength remain on a high level,” explains Detlev Joachimi, head of Durethan product development at LANXESS.

Oil pans with high mechanical strength

The new material fulfills the specifications of various car makers for the low-temperature impact resistance of plastics in exposed engine oil pans. At -30 °C, the Charpy notch impact resistance is 18 kJ/m2 (ISO 179-1eA). As a comparison, Durethan BKV 35 H2.0, a standard polyamide 6 with 35 percent glass fibers, achieves 10 kJ/m2 at this temperature. Compared to the standard polyamide 6, the e-modulus and tensile stress at break of the new material are insignificantly lower at 9,500 MPa and 164 MPa respectively (dry as molded, ISO 527-1,-2). “As a result, we can design oil pans that meet strict demands in terms of stiffness and strength, but also display very high impact resistance,” explains Joachimi.

High heat distortion temperature

Another advantage of this innovative material is its good flow properties and high heat resistance. The heat distortion temperature to ISO 75-1,-2 (HDT A, 1.8 MPa) of 203 °C is nearly as high as that of Durethan BKV 35 H2.0. “The oil pans can therefore be exposed to high continuous operating temperatures without any difficulty,” says Joachimi.

Potential applications in winter sports equipment

With its good resistance at low temperatures, the polyamide also has good prospects outside the car segment, for instance in winter sports. “Conceivable applications include components for ski bindings, sleds and snow mobiles,” says Joachimi.

Detailed information on properties, applications and processing technologies for Durethan and Pocan can be found in the TechCenter of the LANXESS High Performance Materials business unit under www.durethan.com and www.pocan.com.

LANXESS is a leading specialty chemicals company with sales of EUR 7.9 billion in 2015 and about 16,700 employees in 29 countries. The company is currently represented at 55 production sites worldwide. The core business of LANXESS is the development, manufacturing and marketing of chemical intermediates, specialty chemicals and plastics. Through ARLANXEO, the joint venture with Saudi Aramco, LANXESS is also a leading supplier of synthetic rubber. LANXESS is listed in the leading sustainability indices Dow Jones Sustainability Index (DJSI World) and FTSE4Good.

- Gallery