Asia

EMEA

LANXESS Canada Contacts

Contact our Sites in Canada

Media Inquiries

General Inquiries

Please click here to e-mail LANXESS Canada with product inquiries and general requests.

Global Press Releases

2017-04-24

LANXESS innovation for in situ recycling of leather shavings at Hannover Messe

- New plant an example of modular automation

- Resource-efficient manufacturing of leather chemicals

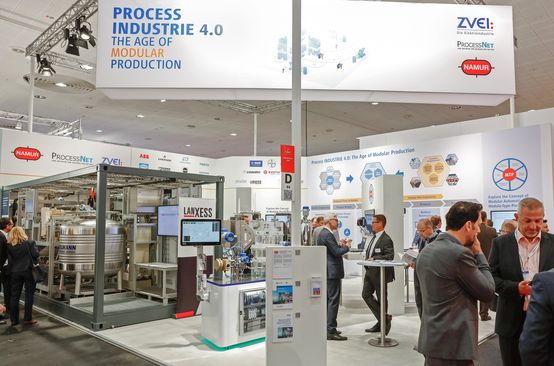

- Part of “Modular Production” show at Booth D44 in Hall 11

- Funding from the German Federal Ministry of Education and Research (BMBF)

A new production plant for recycling shavings in leather production is debuting this year’s Hannover Messe (April 24 – 28). The innovative “ReeL” system for resource-efficient production of leather chemicals will be presented at the Modular Production specialty show, an initiative by Namur, Dechema/ProcessNet and the ZVEI (German Electrical and Electronic Manufacturers’ Association). Visitors will be able to see the system – a good example of technical implementation of ideas in the context of modular automation – at Booth D44 in Hall 11 at the trade fair.

The Leather business unit at LANXESS developed this pilot facility in cooperation with the Leverkusen-based research institute INVITE, with the aim of producing retanning agents from collagen-rich byproducts that accumulate during leather-making and from organic biomass. The plant features a modular design and is intended for use directly on site and in place (in situ) at tanneries. The project partner HELLER-LEDER GmbH Co. KG in Hehlen, Lower Saxony, is set to begin the practical tests beginning in mid-2017.

The project is receiving funding from the German Federal Ministry of Education and Research as part of its “r+Impuls – Innovative Technologien für Ressourceneffizienz – Impulse für industrielle Ressourceneffizienz” (r+Impulse – innovative technologies for resource efficiency – impetus for industrial resource efficiency). This program supports projects that are bringing innovative technologies and products out of the laboratory and into commercial use.

Complete recycling without emissions

A medium-sized tannery produces several metric tons of shavings a day. Using a production facility leased from LANXESS, the company was able to produce enough X-Biomer retanning agent to meet its needs – directly on site. The byproducts used are recycled without leaving any residues; i.e. no waste or emissions are generated during production.

“The goal of the project is to be able to offer X-Biomer to the tanner at a cost comparable to that of procuring commercially available X-Biomer retanning agents,” said Dr. Dietrich Tegtmeyer, who is managing the project at LANXESS. “The lack of logistics outlay should offset the higher production costs for the design. Piloting is being carried out to verify this concept model. In addition, the project will most certainly be beneficial in terms of sustainability.”

Forward-Looking Statements

This company release contains certain forward-looking statements, including assumptions, opinions, expectations and views of the company or cited from third party sources. Various known and unknown risks, uncertainties and other factors could cause the actual results, financial position, development or performance of LANXESS AG to differ materially from the estimations expressed or implied herein. LANXESS AG does not guarantee that the assumptions underlying such forward-looking statements are free from errors nor does it accept any responsibility for the future accuracy of the opinions expressed in this presentation or the actual occurrence of the forecast developments. No representation or warranty (expressed or implied) is made as to, and no reliance should be placed on, any information, estimates, targets and opinions, contained herein, and no liability whatsoever is accepted as to any errors, omissions or misstatements contained herein, and accordingly, no representative of LANXESS AG or any of its affiliated companies or any of such person's officers, directors or employees accept any liability whatsoever arising directly or indirectly from the use of this document.

LANXESS is a leading specialty chemicals company with sales of EUR 7.7 billion in 2016 and about 19,200 employees in 25 countries. The company is currently represented at 75 production sites worldwide. The core business of LANXESS is the development, manufacturing and marketing of chemical intermediates, additives, specialty chemicals and plastics. Through ARLANXEO, the joint venture with Saudi Aramco, LANXESS is also a leading supplier of synthetic rubber. LANXESS is listed in the leading sustainability indices Dow Jones Sustainability Index (DJSI World) and FTSE4Good.

- Gallery