Asia

EMEA

LANXESS Canada Contacts

Contact our Sites in Canada

Media Inquiries

General Inquiries

Please click here to e-mail LANXESS Canada with product inquiries and general requests.

Global Press Releases

2018-05-16

LANXESS attending the SKZ Conference “Plastics in E&E Applications” in Würzburg at Marienberg Fortress on June 5 and 6, 2018

Close to customers and their needs

- New halogen-free, flame-retardant polyamides and polyesters

- LANXESS talk on polyamide compounds with high thermal stability

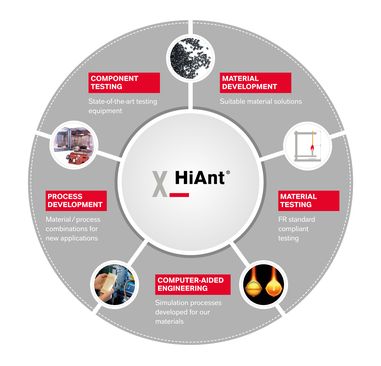

Cologne – As in previous years, the specialty chemicals company LANXESS is participating in the “fuse box meets dryer – Plastics in E&E Applications” conference organized by the Süddeutsches Kunststoffzentrum. The focus of the company’s appearance is on halogen-free, flame-retardant polyesters and polyamides as well as heat-stabilized polyamides. The latter is also the topic of a talk that will held by an expert from the LANXESS High Performance Materials (HPM) business unit. Another focus is on the special services that support customers from the electrical and electronics industry (E&E) along the entire component development chain. “Our broad product range meets worldwide standards of the electrical and electronics industry. Our customers also benefit from our development expertise. Together with them, we are working on new materials and technologies that will help current E&E trends to break through,” explains Marc Marbach, head of the E&E sales segment at HPM.

Extremely flame-retardant and at the same time, thermally resistant to heat aging

The Pocan BFN series of halogen-free, flame-retardant polyesters specifically designed for E&E applications now includes an unreinforced version and several reinforced products with up to 25 percent glass fiber by weight. All achieve the best classification of V-0 (0.4 millimeters) in flammability testing pursuant to the UL 94 (Underwriter Laboratories Inc.) standard. In addition, they also exhibit excellent heat aging resistance. As such, their relative temperature indices pursuant to UL 746B measure at least 140 °C. Further strengths include high stability against UV light, high tracking resistance, and a low tendency to corrode when in contact with metals. Despite its halogen-free flame retardancy, the unreinforced Pocan BFN2502 exhibits a high strain at break of over seven percent. “This easy-flowing material is particularly suitable for components that need to maintain dimensional stability while providing permanent electrical insulation,” explains Alexander Radeck, application developer at HPM. An additional highlight is a reinforced compound that achieves excellent results both on test specimens in glow wire tests pursuant to IEC 60695-2-13 and on finished parts in tests pursuant to IEC 60695-2-11. The development product has the potential to pass the more stringent glow wire tests pursuant to IEC 60335-1 for unattended household appliances (“no flame”).

Easy to color – flame retardant packages without red phosphorus

The halogen-free flame-retardant polyamide 6 and polyamide 66 compounds (PA 6 and 66) in the Durethan FN04 series contain 25 to 45 percent glass fiber by weight. They exhibit long-term thermal stability and particularly high tracking resistance. Their flame retardant packages do not contain red phosphorus, making them easy to color. An outstanding example product is the polyamide 6 Durethan BKV45FN04, which is reinforced with 45 percent glass fiber by weight and has achieved V-0 (0.4 millimeters) classification in UL 94 flammability tests. The easy-flowing construction material exhibits excellent high-voltage tracking resistance. According to Mr. Radeck: “Its exceptional strength and rigidity make it the ideal material for structural components and an excellent substitute for thermosets and die-cast metals.”

Talk on heat-stable PA compounds

In his talk entitled “Durethan Polyamide Compounds for High Temperature Applications,” Thomas Linder, specialist in polyamide product development at HPM, will first describe the differences between PA 6 and 66 compounds in high temperature applications. He will then present heat stabilization systems for Durethan such as XTS3, which have been specially developed for E&E components. These systems do not require metals and halides, which minimizes contact corrosion in components in contact with metals. The third part of his talk will be devoted to the new XTS2 stabilization system, which makes the continuous use of PA 66 compounds at temperatures up to 230 °C possible. Mr. Linder will give his talk on June 5, 2018 at 11:20 a.m.

Forward-Looking Statements

This company release contains certain forward-looking statements, including assumptions, opinions, expectations and views of the company or cited from third party sources. Various known and unknown risks, uncertainties and other factors could cause the actual results, financial position, development or performance of LANXESS AG to differ materially from the estimations expressed or implied herein. LANXESS AG does not guarantee that the assumptions underlying such forward-looking statements are free from errors nor does it accept any responsibility for the future accuracy of the opinions expressed in this presentation or the actual occurrence of the forecast developments. No representation or warranty (expressed or implied) is made as to, and no reliance should be placed on, any information, estimates, targets and opinions, contained herein, and no liability whatsoever is accepted as to any errors, omissions or misstatements contained herein, and accordingly, no representative of LANXESS AG or any of its affiliated companies or any of such person's officers, directors or employees accept any liability whatsoever arising directly or indirectly from the use of this document.

LANXESS is a leading specialty chemicals company with sales of EUR 9.7 billion in 2017 and about 19,200 employees in 25 countries. The company is currently represented at 74 production sites worldwide. The core business of LANXESS is the development, manufacturing and marketing of chemical intermediates, additives, specialty chemicals and plastics. Through ARLANXEO, the joint venture with Saudi Aramco, LANXESS is also a leading supplier of synthetic rubber. LANXESS is listed in the leading sustainability indices Dow Jones Sustainability Index (DJSI World and Europe) and FTSE4Good.

- Gallery