Asia

EMEA

LANXESS Canada Contacts

Contact our Sites in Canada

Media Inquiries

General Inquiries

Please click here to e-mail LANXESS Canada with product inquiries and general requests.

Global Press Releases

2018-10-17

Safer, more efficient, and more environmentally friendly brine purification with ion exchangers from LANXESS

Chelating resins from the Lewatit MDS line proven for brine purification in chlor-alkali electrolysis

Cologne – The new generation of well-established finely dispersed Lewatit ion exchange resins from LANXESS has proven its worth in practice: Lewatit MDS resins significantly increase the efficiency of brine treatment in chlor-alkali electrolysis using the membrane method. They make an effective contribution to preventing damage to the latest generation of ion exchange membranes used for electrolysis, which are becoming more and more sensitive, thus prolonging their service life and reducing the energy costs of the process. Dr. Jenny Barbier, Technical Marketing Manager in the LANXESS Liquid Purification Technologies business unit, will present the new class of ion exchange resins applied to protect these membranes at the FlemionTM Seminar, which will be held in Amsterdam from October 23 to 25, 2018. At the conference, which will be attended by representatives of the global chlor-alkali industry, Barbier will explain the properties of the products and present new case studies in her presentation “New Advances in Brine Purification by Novel Chelating Resins.”

Making brine purification more efficient

In the electrochemical process of chlor-alkali electrolysis, sodium hydroxide, chlorine gas, and hydrogen are produced from a highly concentrated saline solution (brine) – these are important basic chemicals for the production of PVC, paper, cellulose, disinfectants, and bleach, for example. The membrane method was developed for this purpose in the 1970s. It can be run efficiently and safely, offers energy savings of around 25 percent compared to other processes and does not require mercury or asbestos. Due to these and other advantages, it has been used for more than two decades for all new plants and older plants are increasingly being converted to the membrane method. Since impurities can irreversibly damage the cost-intensive fluorinated ion exchange membranes used in electrolysis, the brine is finely purified using ion exchangers.

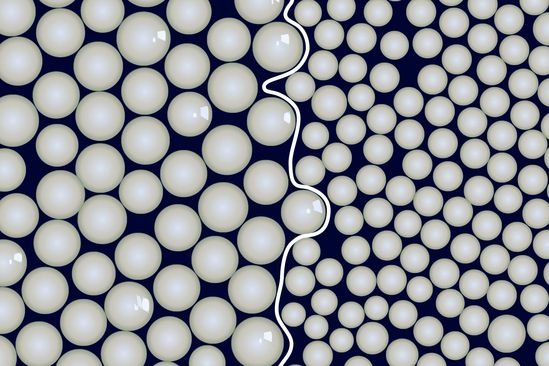

With the particularly fine monodisperse, macroporous chelating resins of the Lewatit MDS series, brine purification in chlor-alkali electrolysis using the membrane method can be made much more efficient. The decisive difference between the new resin types and those previously offered is the bead diameter. This is only 390 µm for the MDS types (Mono Disperse Small, such as Lewatit MDS TP 208) and is thus around 40 percent smaller than for the Lewatit MonoPlus TP 208, which is also monodisperse. As a result of this difference, the MDS types are characterized by improved kinetics, a higher degree of regeneration and a significantly increased total and operating capacity especially for alkaline earth cations. They have optimal mechanical and osmotic stability.

Barium and strontium ions are separated particularly efficiently from the brine. “Because of the low selectivity of many other resins and the slow exchange kinetics, this is particularly remarkable – and is increasingly the focus of customers,” says Barbier. The chelating resin also binds the lighter elements of the alkaline earth group, i.e. calcium and magnesium. “The improved removal rates are an important advantage because the reduced leakage helps to increase the service life of the electrolysis membranes. In this respect, the MDS resins have already anticipated the continuously progressing membrane development by allowing the user to protect their membranes better through significantly lower concentration tolerances for alkaline earth ions,” explains Barbier.

Many economic advantages

The Lewatit MDS chelating resins open up a whole series of economic advantages for the electrolysis operator, particularly in terms of significant savings in energy costs, and are primarily based on the following effects:

· Longer lifetime of membranes and resin

· Lower operating costs due to lower regenerant requirements and wastewater reduction

· Longer cycle times in operation

· Higher throughput in brine preparation

The new resin types are already being used successfully on an industrial scale. In her presentation at the FlemionTM Seminar, Barbier explaines the benefits for the industry using two case studies. One from a leading European PVC supplier from Germany and one from a chemical manufacturer from South India that ensures a supply of basic and specialty chemicals.

Forward-Looking Statements

This company release contains certain forward-looking statements, including assumptions, opinions, expectations and views of the company or cited from third party sources. Various known and unknown risks, uncertainties and other factors could cause the actual results, financial position, development or performance of LANXESS AG to differ materially from the estimations expressed or implied herein. LANXESS AG does not guarantee that the assumptions underlying such forward-looking statements are free from errors nor does it accept any responsibility for the future accuracy of the opinions expressed in this presentation or the actual occurrence of the forecast developments. No representation or warranty (expressed or implied) is made as to, and no reliance should be placed on, any information, estimates, targets and opinions, contained herein, and no liability whatsoever is accepted as to any errors, omissions or misstatements contained herein, and accordingly, no representative of LANXESS AG or any of its affiliated companies or any of such person's officers, directors or employees accept any liability whatsoever arising directly or indirectly from the use of this document.

LANXESS is a leading specialty chemicals company with sales of EUR 9.7 billion in 2017 and about 19,200 employees in 25 countries. The company is currently represented at 74 production sites worldwide. The core business of LANXESS is the development, manufacturing and marketing of chemical intermediates, additives, specialty chemicals and plastics. LANXESS is listed in the leading sustainability indices Dow Jones Sustainability Index (DJSI World and Europe) and FTSE4Good.

- Gallery