Asia

EMEA

LANXESS Canada Contacts

Contact our Sites in Canada

Media Inquiries

General Inquiries

Please click here to e-mail LANXESS Canada with product inquiries and general requests.

Global Press Releases

2012-10-26

LANXESS at BioEnergy Decentral 2012, November 13 to 16,<br> Hanover, Hall 21, Stand 21/C06

Innovative specialty products for biogas desulfurization

Sustainable iron oxides that are easy to meter

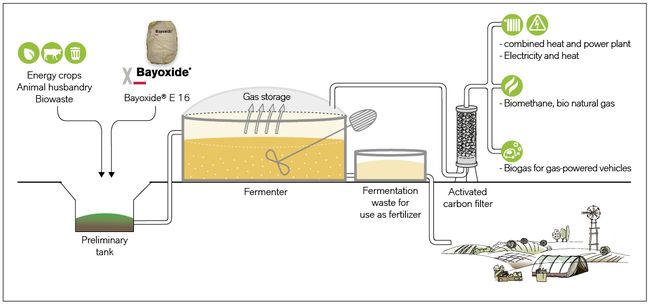

Specialty chemicals company LANXESS is showcasing its newly developed iron oxide for biogas desulfurization at BioEnergy Decentral in Hanover, Germany, from November 13 to 16, 2012. “This international trade show for decentralized energy supply, where some 280 exhibitors will be presenting their products and services, is the ideal forum for introducing biogas producers to our low-cost alternative to conventional desulfurization methods,” says Gregor Hermanns, technical oxides expert in the LANXESS Inorganic Pigments business unit. Thanks to its high purity, Bayoxide E 16 is very effective and already removes much of the hydrogen sulfide generated by the fermentation of organic substances in the fermentation reactor. When it comes to injection into the public gas grid, the residual hydrogen sulfide content is already so low that the cost of secondary biogas desulfurization can be significantly reduced.

Biogas is a trend today because it is an ecological, resource-conserving and climate-neutral energy source. In Germany alone, the number of biogas plants has increased by a factor of 10 over the last 13 years.

In a biogas plant, agroindustrial, private and/or commercial biowastes are decomposed and fermented under anaerobic conditions. Fermentation produces a gas comprised chiefly of methane, which in most cases is used directly on site to drive a generator. Depending on the starting materials, biogas contains fluctuating levels of hydrogen sulfide, on average about 500 milligrams per cubic meter. The hydrogen sulfide must be removed from the gas because of its toxicity, odor and above all the corrosive effect of the sulfur compounds on the fermentation reactor and generator. Without effective desulfurization, the hydrogen sulfide may also cause damage to any catalytic exhaust gas converter which may be fitted to the generator and this could result in excessive waste gas emissions.

High performance and easy handling

Because Bayoxide E 16 can be added to the fermentation reactor directly, in its original packaging, metering is simple and dust-free. No costly metering systems are required. “Iron oxide is neither a hazardous material nor a water contaminant. The product requires no special storage and personnel need not be trained in accordance with the German Ordinance on Dangerous Goods,” says Hermanns. What is more, no danger exists of explosive mixtures of methane and atmospheric oxygen forming due to the incorrect addition of too much product.

Bayoxide E 16 reacts with hydrogen sulfide to form iron sulfide and sulfur, which as substances occurring naturally in soil can be used to fertilize fields, together with the fermentation residue. It has a high active ingredient content and fulfills the strict requirements of the German fertilizer regulations.

“Alongside the color applications, which are still the most important segment for LANXESS Inorganic Pigments, technical applications will continue to gain significance,” predicts Jörg Hellwig, head of the global inorganic pigment business. “Our iron oxide and chrome oxide pigments are used in a wide variety of fields. Biogas desulfurization is only one of them, and new applications are being added all the time, recently, for example, the use of iron oxides as a raw material for cathodes in lithium-ion batteries for electric vehicles.”

The Inorganic Pigments business unit is part of LANXESS’ Performance Chemicals segment, which achieved sales of EUR 2.13 billion in fiscal 2011.

LANXESS is a leading specialty chemicals company with sales of EUR 8.8 billion in 2011 and currently around 16,900 employees in 31 countries. The company is currently represented at 49 production sites worldwide. The core business of LANXESS is the development, manufacturing and marketing of plastics, rubber, intermediates and specialty chemicals. LANXESS is a member of the leading sustainable indices Dow Jones Sustainability Index (DJSI) World and FTSE4Good.

- Gallery