Asia

EMEA

LANXESS Canada Contacts

Contact our Sites in Canada

Media Inquiries

General Inquiries

Please click here to e-mail LANXESS Canada with product inquiries and general requests.

Global Press Releases

2012-03-30

Expertise in water treatment “Made in Bitterfeld”

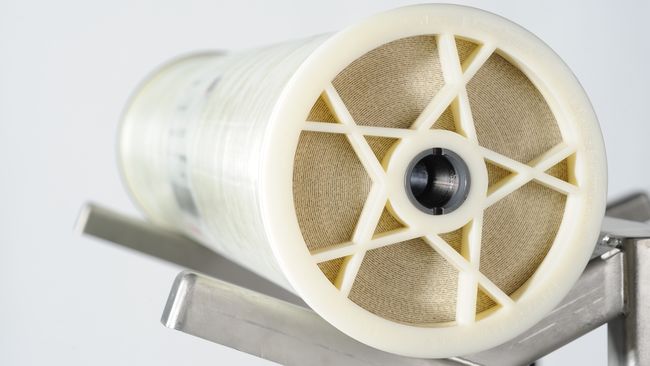

New on the market: RO Membrane elements from LANXESS

Specialty chemicals company presents Lewabrane product line

With immediate effect, specialty chemicals company LANXESS is offering Lewabrane membrane separation elements for reverse osmosis to complement its established Lewatit ion exchange resins. The former will be produced at the new production unit in Bitterfeld that went on stream last fall. Initially, customers will be able to buy two RO element types with different capacities that are based on polyamide thin-film composite membranes. Further, other RO element types will be added to the product range soon.

The main field of application for the currently available RO membrane separation elements is desalination of brackish water needed in many industrial applications, including the production of boiler feed water required in power stations. RO membrane and ion exchange water treatment processes complement each other perfectly, and the high treated water quality helps to prolong the service life of, for example, turbines and steam generators via protection against fouling, scale formation and corrosion.

Another application for the new Lewabrane RO membrane elements is the preparation of feedwater that customers can use for electrodeionization (EDI) applications. The EDI process allows for the production of ultrapure water with very low electrical conductivity without the need for regeneration chemicals. High performance RO membranes can provide a reduced load on the downstream EDI process improving cost performance. These membrane based processes have been increasingly adopted by the water treatment industry for preparation of high purity water.

“The combination of RO membrane separation and ion exchange ensures that efficiency and economy can go hand in hand in this and similar applications. This is true synergy,” says Alan Sharpe, Manager of Strategic Projects in LANXESS' Ion Exchange Resins business unit. Since LANXESS has products, experience and services for both technologies, this combination of processes is particularly attractive. “Our tried and tested Lewatit ion exchange resins and the new Lewabrane membrane elements can both demonstrate good value to water treatment customers,” adds Sharpe.

As premium products, membrane elements in the Lewabrane RO product family meet top quality standards and comply with all requirements for industrial use. With a standard length of 40 inches (1,016 mm) and a diameter of eight inches, Lewabrane RO B400 HR has an active membrane surface area of 400 square feet (37.2 m²). Salt rejection is 99.7 % for a daily permeate flow rate of 37.9 m³ (average value under standard industry reference conditions; salt concentration in the feed: 2000 ppm, 225 psi, pH 7, 25 °C, and a single element recovery of 15 %).

The Lewabrane RO B090 HF 4040 element has the same length but a diameter of only four inches and an active membrane surface area of 90 square feet (8.7 m²). “Thanks to a new ATD (anti-telescoping device) design, the surface area of the membranes exceeds that of other commercially available elements by almost 6 percent,” explains Sharpe. The new LANXESS filtration element owes its superior average permeate flow rate of 2500 gallons per day (9.4 m³ per day) under standard conditions at a rejection level of 99.5 % to the greater active surface area of the RO membrane available inside the RO element.

Detailed information about the company’s ion exchange resin portfolio is available on the Internet at www.lewatit.com. Information on the membrane filtration elements can be found on the website www.lewabrane.com.

The Ion Exchange Resins business unit belongs to LANXESS’ Performance Chemicals segment, which achieved total sales in fiscal 2011 of EUR 2.13 billion.

LANXESS is a leading specialty chemicals company with sales of EUR 8.8 billion in 2011 and currently around 16,500 employees in 30 countries. The company is at present represented at 48 production sites worldwide. The core business of LANXESS is the development, manufacturing and marketing of plastics, rubber, intermediates and specialty chemicals. LANXESS is a member of the leading sustainable indices Dow Jones Sustainability Index (DJSI) World and FTSE4Good.

- Gallery