Asia

EMEA

LANXESS Canada Contacts

Contact our Sites in Canada

Media Inquiries

General Inquiries

Please click here to e-mail LANXESS Canada with product inquiries and general requests.

Global Press Releases

2016-10-19

LANXESS presents new PBT compounds

Halogen-free alternative with high mechanical performance

- Extremely fire-resistant

- Higher tracking resistance and dielectric strength

- Enhanced UV and heat resistance

For a long time, halogen-free flame-retardant PBT (polybutylene terephthalate) compounds were inferior to their counterparts with halogen-based flame retardance packages. Yet for environmental reasons, they were still used in numerous applications. Their performance has since improved significantly by comparison and they are now a realistic alternative from a technical perspective. One example is Pocan BFN glass-fiber-reinforced compounds, which LANXESS has used to expand its range of fire-resistant thermoplastics. “They exhibit better electrical performance and greater thermal and UV stability, for example. Their mechanical properties are only slightly inferior and can be adapted to the level of their counterparts with halogen-based flame retardance via the glass fiber content,” explains Alexander Radeck, an expert in flame-retardant PBT materials at LANXESS.

High flame retardance to UL 94

The glass fiber content of the new compounds ranges from 13 to 25 percent. They are a further development of Pocan DP BFN 4230, which has been highly successful on the market and is used to manufacture connectors for electrical appliances and housings for alternating-current tubular drives, among other applications. With their innovative halogen-free flame-retardant additives, they pass the fire tests to standard UL 94 of the U.S. testing organization Underwriters Laboratories with the best classification V-0 for a test specimen up to 0.4 millimeters thick. “An extremely low tendency to contact corrosion with metals was also confirmed in realistic application testing,” says Radeck, explaining a further benefit.

Excellent opportunities for use in photovoltaics

Tracking resistance is much higher than for PBT grades with halogen-based flame retardance. The result is a CTI (Comparative Tracking Index, UL746A) with the best possible performance level category PLC 0 and an IPT (Inclined Plane Tracking, UL 746A) value of at least 60 minutes at 1.5 kV. “Designers gain greater freedom in component design thanks to the high tracking resistance. This is because they can make electrical assemblies even more compact without having to worry about short circuits and equipment faults due to leakage currents,” says Radeck. The dielectric strength, which is a measure of an insulating material’s resistance to high voltage, is also high with values of around 30 kV/mm (ISO 60243-1) and is not dependent on the level of humidity. “As well as use for conventional electrical appliances, the electrical properties of our new PBT compounds also open up significant potential in photovoltaics,” explains Radeck.

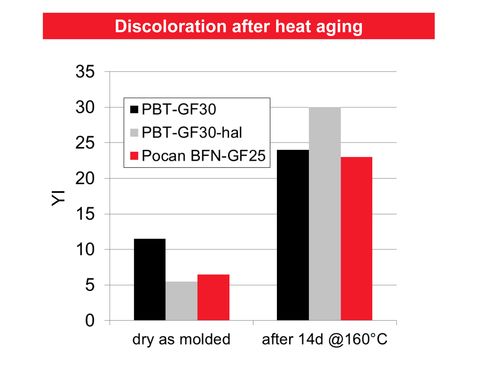

Virtually no yellowing when subjected to thermal stresses

A further strength of the new PBT grades is their resistance to thermal aging at higher temperatures. Their relative thermal indices (RTI) achieve values to UL 746B of up to 150 °C (0.4 millimeters). “After UV and thermal aging, the greater long-term heat resistance in air also leads to greater color stability compared to PBTs with halogen-based flame retardance packages,” says Radeck: “This makes the materials ideal for manufacturing housings for LEDs, for instance.”

Stable manufacturing process, lower density

The new PBT materials are designed to ensure they can be injection-molded in a wide processing window and stable process. Their shrinkage behavior is so similar to PBT compounds with halogen-based compounds that they can be processed in the same molds. “Their density is up to 8 percent lower, which increases cost-effectiveness as a result of the reduced material use,” says Radeck. An important factor in identifying components is that the new materials can be labeled with very high contrast and precision using lasers.

Further details on the properties, applications and processing technologies of Durethan and Pocan can be found at www.durethan.com and www.pocan.com in the TechCenter of LANXESS’s High Performance Materials business unit.

LANXESS is a leading specialty chemicals company with sales of EUR 7.9 billion in 2015 and about 16,700 employees in 29 countries. The company is currently represented at 55 production sites worldwide. The core business of LANXESS is the development, manufacturing and marketing of chemical intermediates, specialty chemicals and plastics. Through ARLANXEO, the joint venture with Saudi Aramco, LANXESS is also a leading supplier of synthetic rubber. LANXESS is listed in the leading sustainability indices Dow Jones Sustainability Index (DJSI World) and FTSE4Good.

- Gallery