Asia

EMEA

LANXESS Canada Contacts

Contact our Sites in Canada

Media Inquiries

General Inquiries

Please click here to e-mail LANXESS Canada with product inquiries and general requests.

Global Press Releases

2010-06-16

Grafted EP(D)M from LANXESS makes polyamides impact-resistant

Drawing on plentiful resources

LANXESS, the pioneer of synthetic rubber, has added a new grade to its portfolio of ethylene-propylene rubbers. Supplied as free-flowing pellets, Buna EP XT 2708 VP is an EP copolymer grafted with 0.8 percent maleic anhydride (MAH) that is ideal for applications such as modifying the impact resistance of engineering plastics such as polyamides. For example, thermoplastics modified with Buna EP XT 2708 VP exhibit particularly impressive low-temperature performance. In addition, the new EPM grade can also enhance the mechanical performance of wood/plastic composites and improve the rubber/fiber bond in fabric-reinforced rubber items such as hoses and belts.

“In principle, using grafted ethylene-propylene rubbers to enhance the impact resistance of engineering plastics is not a new idea,” says John Beelen, Head of Global Business Development Business Line EPDM at LANXESS, explaining the concept behind the new product. “However, we are the only EPDM manufacturer in the world that can produce this elastomer using both the solution process and the high-tech suspension process. This allows us, for example, to offer our customers more than 40 different grades of EPDM. It is only logical to utilize this diversity for the production of grafted grades, too. Our trial product Buna EP XT 2708 VP is our first successful step in this direction – and many more are in the pipeline.”

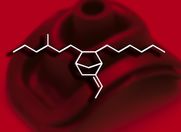

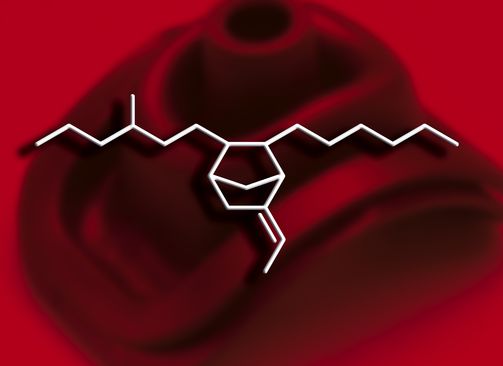

The “grafting” of EP(D)M with maleic anhydride – a process known as “reactive extrusion” – involves attaching polar side groups to the non-polar elastomer. These polar side groups then boost the polymer’s compatibility with other polar plastics such as polyamides and polybutylene terephthalates. The modification also improves the adhesion of the elastomer to materials such as wood and polyamide fibers, making Buna EP XT 2708 VP an ideal bonding agent between non-polar polymers and the surfaces of these strengthening materials.

Nonetheless, the properties of the end product depend to a large extent on the detailed composition of the grafted EPM grade. For example, the more amorphous the elastomer is, the better the low-temperature flexibility of an impact-resistance-modified polyamide, while too large a crystalline content robs the polymer of its elasticity. “Crystallinity is determined by a number of factors including ethylene (C2) content,” explains Beelen: “If it is too high, the material behaves more like a thermoplastic.” However, if the C2 content is too low, the product cannot be processed into pellets, which is crucial for enabling plastics compounders to add the modifier just like a conventional thermoplastic material. Ultimately, the material – like Buna EP 2708 VP – also has to make the grade when it comes to cost efficiency.

“This is where it all comes down to know-how and of course to suitable grades of EPDM. And this is where LANXESS has been able to draw on plentiful resources. When it came to manufacturing our new, grafted Buna grade, we turned to Buna EP G 2070, a material with an ethylene content of 73 percent. In PA6, this grade in itself yields low-temperature impact strengths that easily outclass compounds made from other grafted ethylene propylene rubbers,” states Beelen. “Tests with grades that exhibit a lower ethylene content are nearing completion and are already yielding promising results.”

#LANXESS is a leading specialty chemicals company with sales of EUR 5.06 billion in 2009 and currently around 14,300 employees in 23 countries. The company is represented at 42 production sites worldwide. The core business of LANXESS is the development, manufacturing and marketing of plastics, rubber, intermediates and specialty chemicals.

- Gallery