Asia

EMEA

LANXESS Canada Contacts

Contact our Sites in Canada

Media Inquiries

General Inquiries

Please click here to e-mail LANXESS Canada with product inquiries and general requests.

Global Press Releases

2013-07-01

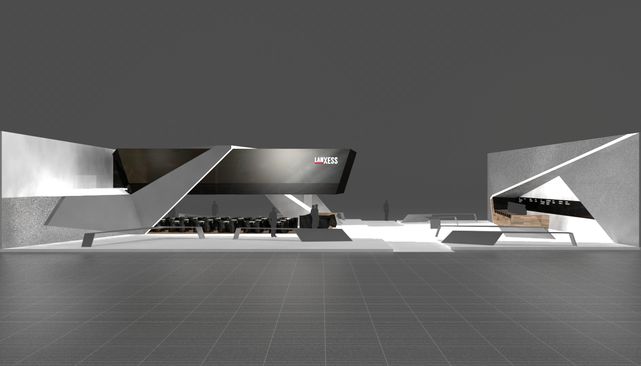

LANXESS press conference ahead of K 2013

Innovative products for green mobility

LANXESS will be focusing on innovative solutions for green mobility at K 2013 in Düsseldorf. “Worldwide there are more than one billion cars on our roads, and by 2050 this figure is expected to rise to 2.5 billion. Sustainable mobility is therefore becoming a global megatrend. With numerous products and technologies, LANXESS is already a pioneer in green mobility,” said Dr. Werner Breuers, member of the LANXESS Board of Management, speaking to international journalists at a press conference in Düsseldorf ahead of K 2013. Among other things, LANXESS will be using the trade fair to focus on high-performance rubber and rubber chemicals for green tires with low rolling resistance, high-tech thermoplastics for lightweight construction and rubber based on sustainable raw materials.

Application-oriented culture of innovation

In 2012, specialty chemicals company LANXESS generated almost 20 percent of its Group sales with products for green mobility. “Our culture of innovation is focusing systematically on the needs of our customers and we work closely with them to develop innovative solutions that can be launched on the market as quickly and cost-effectively as possible,” said Breuers. Last year, LANXESS invested EUR 192 million – around 2.1 percent of its sales – in research and development, some 33 percent more than in the previous year. “In particular, our culture of innovation aims to pay dividends on the growth markets in China, India, Russia and Brazil, where we are strengthening our presence significantly,” said Breuers. For instance, a butyl rubber plant with an annual capacity of 100,000 metric tons was opened in Singapore a month ago.

EPDM – focus on ACE technology and growth markets

LANXESS is looking to capture new market share worldwide in Keltan ethylene-propylene high-performance elastomers (EPDM) with advanced production technologies, investment in growing markets and a focused portfolio. Innovative ACE technology plays a key role in this, producing EPDM without the use of chlorine in a high-purity process and with a composition that can be controlled with a degree of detail that has hardly been possible in the past. “Seven grades in the EPDM portfolio have the ACE technology to thank for their superior performance. It is also enabling us to add new EPDM grades to our portfolio,” said Dr. Torsten Derr, head of the Keltan Elastomers business unit. Its investments include the world’s largest EPDM plant at Changzhou in China, with an annual capacity of up to 160,000 metric tons. Start of production is scheduled for 2015.

Technical rubber grades – highly specific problem solvers

The High Performance Elastomers business unit, one of the world’s leading suppliers of technical rubber, is committed to developing innovative specialties as highly specific problem solvers. It is pursuing a four-prong strategy in nitrile-butadiene rubber (NBR). As well as cost-effective NBR grades and diversification of the portfolio through customer-specific materials, for example, the focus is also on innovative NBR grades and new Baymod powder NBR grades. An innovative compounding step in polychloroprene production extends the range of applications for this rubber. “This has helped us develop two new product families, Baypren HP and GF. Baypren HP includes products with properties that are not yet available on the market,” said Jan Paul de Vries, head of High Performance Elastomers. Among the polyethylene-vinyl acetate (EVM) Levapren materials under development, a grade for impact resistance modification of polylactic acid is highly promising. The focal point of the business unit’s investment activities is Asia. For instance, a nitrile rubber plant with an annual capacity of 30,000 metric tons was opened in Nantong in China in May 2012 in conjunction with a partner.

High-tech thermoplastics – exceptional position in lightweight construction

The High Performance Materials (HPM) business unit is looking to showcase its unique global position in lightweight automotive construction based on Durethan and Pocan high-tech polyamides and polyesters at K 2013. This was recently reinforced by the acquisition of Bond-Laminates, an outstanding manufacturer and supplier of continuous fiber-reinforced thermoplastic performance composites marketed under the TEPEX brand. “We are now one of the few thermoplastics manufacturers in the world that can supply performance composites and compounds proven in large-scale production, complete with the associated applications know-how for the volume production of lightweight components,” said Dr. Michael Zobel, head of HPM. The company will harness its unique position in lightweight construction first and foremost to further expand business on the growth markets and continue the globalization process with new production facilities. Among the examples of HPM lightweight construction expertise cited by Zobel were the first front end carriers consisting entirely of polyamide 6 and the first car brake pedal made of polyamide reinforced with continuous glass fibers and suitable for large-scale series production.

LANXESS is a leading specialty chemicals company with sales of EUR 9.1 billion in 2012 and roughly 17,400 employees in 31 countries. The company is currently represented at 50 production sites worldwide. The core business of LANXESS is the development, manufacturing and marketing of plastics, rubber, intermediates and specialty chemicals. LANXESS is a member of the leading sustainability indices Dow Jones Sustainability Index (DJSI) World and FTSE4Good as well as the Carbon Disclosure Leadership Index (CDLI).

- Gallery