Asia

EMEA

LANXESS Canada Contacts

Contact our Sites in Canada

Media Inquiries

General Inquiries

Please click here to e-mail LANXESS Canada with product inquiries and general requests.

Global Press Releases

2013-10-22

LANXESS celebrates 75 years of production of ion exchange resins for the treatment of water

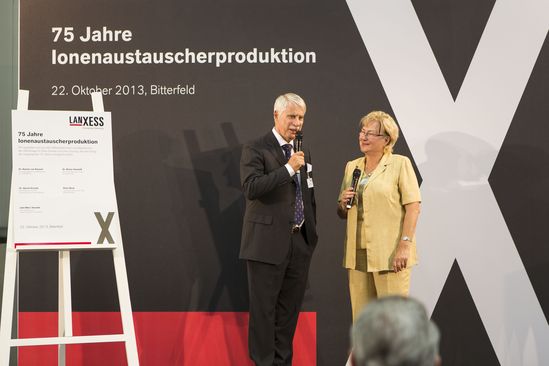

- Anniversary event with Reiner Haseloff, State Premier of Saxony-Anhalt, and Bitterfeld-Wolfen Mayor Petra Wust

- Industrial-scale production of cleaning polymer beads premiered in Bitterfeld-Wolfen in 1938

- Specialty chemicals company today is a one-stop-shop supplier of high-tech solutions for clean water

The history of water treatment is tightly tied to that of Bitterfeld-Wolfen. The city on the Mulde is the birthplace of ion exchange resins, high-performance polymer beads that can be used to remove pollutants from liquids and thus help to improve water quality. Industrial-scale production of the tiny resin beads began for the first time ever in Wolfen 75 years ago. With ion exchange resins and also the production of RO membrane elements (reverse osmosis), LANXESS AG in Bitterfeld and other locations makes an important contribution to ensuring access to clean drinking water in all parts of the world.

“The subject of water is one of the central megatrends of our time. Worldwide, clean water is becoming ever more precious, because consumption and the world’s population are increasing constantly. LANXESS delivers innovative products and solutions to meet the challenges of an increasingly difficult water supply situation around the world,” said Rainer van Roessel, member of the LANXESS AG Board of Management, at the anniversary event this Tuesday in Bitterfeld-Wolfen. “We are making targeted use of our know-how to improve the quality of life for people the world over.”

Reiner Haseloff, State Premier of Saxony-Anhalt, emphasized the importance of the tradition-rich chemical industry for the site. “Today's anniversary celebration underscores how tightly intertwined LANXESS has become with Bitterfeld-Wolfen. The commitment of prestigious companies such as LANXESS is a seal of quality for Saxony-Anhalt as an industrial location. One key advantage enjoyed by Saxony-Anhalt are the chemical parks, such as here in Bitterfeld-Wolfen, where companies can utilize infrastructure and services together and thus more cost-effectively. The last few years show that we are on the right path with this strategy,” said Haseloff.

“The development of the ion exchange resins was one of many groundbreaking inventions made at the tradition-rich Bitterfeld-Wolfen industrial site,” said Petra Wust, Mayor of the city of Bitterfeld-Wolfen. “As Mayor, I am proud that this process has been used successfully around the world for 75 years now. Hardly any other product developed here at the site can look back on such a long history of success. Bayer AG played a major role in this success following reunification, as has LANXESS AG, which has conducted production operations in state-of-the-art facilities here since 2004,” she continued. “In particular, the decision by LANXESS AG to expand the plant complex in Bitterfeld-Wolfen is a testament to both the competitiveness of our industrial site and the attachment of the specialty chemicals company to the region, for which I am very grateful.”

Bitterfeld: Most important LANXESS site for the megatrend water

The specialty chemicals company LANXESS produces premium water treatment products in Bitterfeld and Leverkusen, Germany, as well as in Jhagadia, India. In Bitterfeld, its most important site for the megatrend water, the specialty chemicals company operates a complex of plants for the production of monodisperse ion exchange resins. It is the largest and most modern plant of its kind worldwide. Two years ago, LANXESS also inaugurated a new production plant for RO membrane technology for use in water treatment applications at the Bitterfeld site at an investment cost of some EUR 30 million. “And we continue to bolster our water treatment business,” said van Roessel. “The demand for ion exchange resins for water treatment is growing globally at a roughly four percent annual rate. We are therefore currently investing EUR 10 million at our Leverkusen site in a new production line for weakly acidic cation exchange resins and in an advanced filling and packaging plant.” The construction work, which is intended to increase production capacities at the site on the Rhine, is scheduled to be completed by mid-2014.

“Our Lewatit-brand ion exchange resins and Lewabrane RO membrane elements make us not only a leading one-stop-shop supplier in the water treatment field, but also the only producer of these membrane elements in Europe,” said Jean-Marc Vesselle, Head of the LANXESS Liquid Purification Technologies business unit. “Together, the two brands' products form a highly efficient purification system that can also be used for the desalination of seawater to obtain drinking water.”

Potent bead for household and industrial use

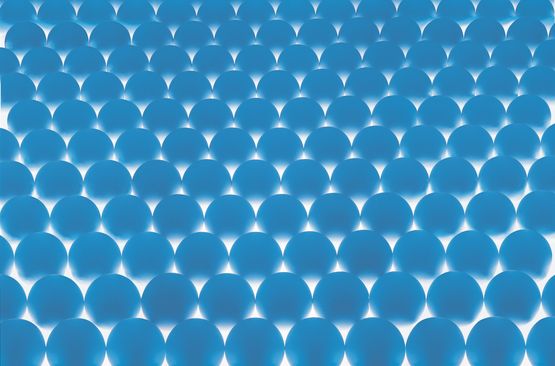

The way ion exchange resins work is delightfully simple – The small polymer beads less than one millimeter thick bind undesirable substances in liquids and release harmless substances in their place. Possible applications include the softening of water in dishwashers and decarbonization in household water filters. In power plants, the polymer beads are used to produce highly pure water and steam. This prevents deposits and corrosion and increases efficiency, operational reliability and service life. In addition, ion exchange resins help to selectively remove heavy metals and organic pollutants from both groundwater and industrial wastewater.

Eventful history of ion exchange resins

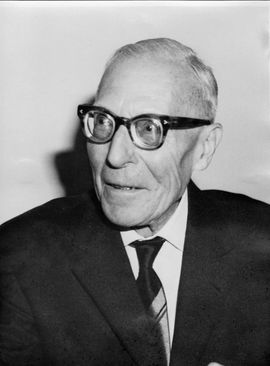

Wolfen was the cradle of ion exchange resins in the 1930s. Paul Robert Griesbach and his employees conducted their research here, and the first prototypes, which achieved market maturity beginning in 1936, were also developed here. In 1938, industrial-scale production of ion exchange resins began under the brand name WOFATIT, which was officially registered on August 1, 1939. Even then Griesbach recognized that a multitude of areas of application could be derived from the myriad possible variations of the starting materials.

Following World War II, production continued at the state-owned VEB Farbenfabrik Wolfen. With the assistance of Wolfen experts who traveled to West Germany, an additional production site was established in Leverkusen in the 1950s. The brand name of these ion exchangers: LEWATIT.

The development of macroporous resins in the 1960s enabled large volumes of water to be treated economically. VEB Chemiekombinat Bitterfeld, into which VEB Farbenfabrik Wolfen was integrated, was established in 1969. The next two decades were marked by technical innovations. Counterflow technology was introduced in the 1970s, and monodisperse ion exchange resins, whose particles are all exactly the same size, were developed in the 1980s.

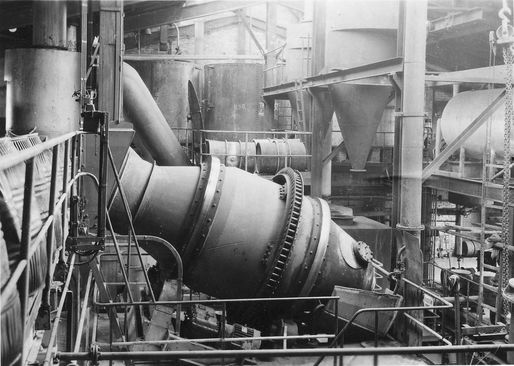

In 1991, shortly after German reunification, Bayer took over the distribution of the Bitterfeld WOFATIT resins. Construction started in 1996 on a new ion exchange plant complex and IAB GmbH on the grounds of Bayer Bitterfeld GmbH on the outskirts of the former chemical works. In order to hold on to the production workers, three “legacy” units remained in operation until the start of production by the new plants. The new plant complex commenced operation in January 1999.

With the spin-off from Bayer, IAB Ionenaustauscher GmbH joined the newly established specialty chemicals company LANXESS in 2004. Three years later, the capacities for monodisperse ion exchange resins at the Bitterfeld site were expanded. On January 21, 2010, ground was broken in Bitterfeld for a new plant for membrane separation technology. Just 20 months later, in September 2011, LANXESS officially inaugurated its state-of-the-art production facility for the production of reverse osmosis membrane elements for water treatment in Bitterfeld.

LANXESS Liquid Purification Technologies

The Liquid Purification Technologies (LPT) business unit currently has a workforce of around 500 worldwide, of which some 300 are located in Germany (130 thereof in Bitterfeld). LPT belongs to LANXESS’ Performance Chemicals segment, which achieved total sales of EUR 2.2 billion in 2012.

LANXESS is a leading specialty chemicals company with sales of EUR 9.1 billion in 2012 and roughly 17,500 employees in 31 countries. The company is currently represented at 52 production sites worldwide. The core business of LANXESS is the development, manufacturing and marketing of plastics, rubber, intermediates and specialty chemicals. LANXESS is a member of the leading sustainability indices Dow Jones Sustainability Index (DJSI) World and FTSE4Good as well as the Carbon Disclosure Leadership Index (CDLI).

- Gallery