Asia

EMEA

LANXESS Canada Contacts

Contact our Sites in Canada

Media Inquiries

General Inquiries

Please click here to e-mail LANXESS Canada with product inquiries and general requests.

Global Press Releases

2016-01-29

LANXESS at the AMTA/AWWA Membrane Technology Conference & Exposition, February 1-5, 2016, San Antonio, Texas, United States, Stand 130

LANXESS launches new reverse osmosis elements on the market

Better performance thanks to innovative feed spacers

Specialty chemicals company LANXESS is taking advantage of this year's Membrane Technology Conference & Exposition, hosted by the American Membrane Technology Association (AMTA) and the American Water Works Association (AWWA), to introduce novel reverse osmosis (RO) elements from its Lewabrane product line that display improved performance. The conference and exposition are being held in San Antonio, Texas, from February 1 to 5, 2016.

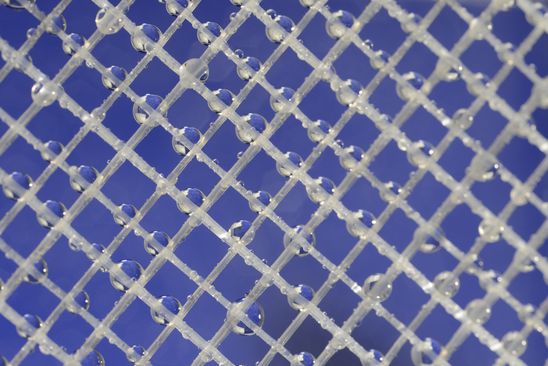

“We succeeded in a very short time in developing a market-ready, novel feed spacer used in the membrane element. It provides for optimized flow in the RO element and thus lower energy consumption. Combining it with our proven, Lewabrane-brand reverse osmosis membrane results in high-performance products suitable for any number of applications,” explained Dr. Carsten Schellenberg, head of Research and Development at the membrane facility operated by the Liquid Purification Technologies (LPT) business unit in Bitterfeld, Germany. Initially, two, new products are to be introduced: Lewabrane B400 LE ASD and Lewabrane B400 FR ASD. Optimized for applications in brackish water, these elements have standard geometries (length: 40 inches, diameter: 8 inches) and are characterized by very low energy consumption (LE = low energy) and high fouling resistance (FR = fouling resistant).

Successful development partnership

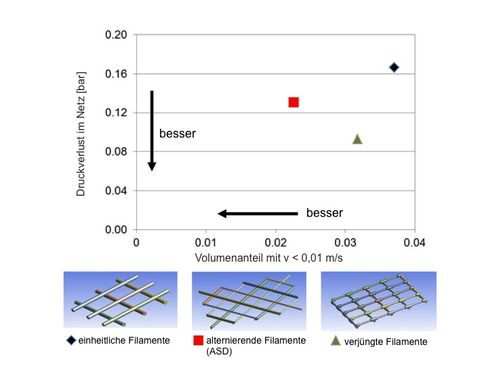

The new products in the Lewabrane line were developed as part of a cooperative research project involving LANXESS as well as regional and international partners. The feed spacers incorporated in the membrane elements are multifunctional. They create space between the membrane surfaces for fast-flowing water, support the membrane in the process and cause turbulent water flow. Although turbulent flow helps to lower salt concentrations at the surface of the membrane, and to reduce the extent of concentrate polarization, it also causes an increased pressure drop compared, for instance, to laminar flow. The optimal design of the feed spacers therefore is of critical importance to the properties of the elements. Filaments or strands of different thickness are used for the novel feed spacers. The new product family is named after this alternating strand design (ASD).

Lower energy consumption, longer dwell times

Computational fluid dynamic (CFD) simulations had previously indicated that RO elements with ASD feed spacers would indeed be capable of achieving higher performance levels. Tests of prototypes later fabricated as part of the project confirmed these calculations. The prototypes were shown to have a significantly lower pressure drop than standard grades and competitor products. Furthermore, the tendency towards scaling in the element was reduced. “With the new elements, we expect energy usage to decline and dwell times to be extended,” said Schellenberg, summarizing the results.

The details of these results were compiled on a poster “Novel Feed Spacer Design for RO Elements with Enhanced Performance for Waste Water Treatment” by Carsten Schellenberg, Julien Ogier and Stefan Lehmann, which is to be presented at the AMTA/AWWA conference. It shows operating cost calculations based on a waste water treatment scenario, which illustrate the considerable cost-cutting potential of ASD elements.

Pooled competence for reverse osmosis and ion exchange

LANXESS offers customers a wide range of products and comprehensive expertise in two important areas of water treatment: Membrane technology and ion exchange. Ion exchange resins from the extensive Lewatit line have been synonymous with high performance and quality for over 75 years.

LANXESS proprietary LewaPlus software supports not only the design of reverse osmosis, ion exchange and combined systems for water treatment, but also a detailed and reliable estimation of the investment and operating costs. “The knowledge and experience LANXESS has gained with its Lewabrane and Lewatit grades, and its technological and applications know-how in membrane technology and ion exchange, are continuously being incorporated into our LewaPlus design software,” added Schellenberg.

Detailed information about products from the LANXESS LPT business unit can be obtained online at https://lpt.lanxess.com/en/home/. Brochures and the LewaPlus software can also be downloaded from this website free of charge.

LANXESS is a leading specialty chemicals company with sales of EUR 8.0 billion in 2014 and about 16,300 employees in 29 countries. The company is currently represented at 52 production sites worldwide. The core business of LANXESS is the development, manufacturing and marketing of plastics, rubber, intermediates and specialty chemicals. LANXESS is a member of the leading sustainability indices Dow Jones Sustainability Index (DJSI World) and FTSE4Good.

- Gallery