Asia

EMEA

LANXESS Canada Contacts

Contact our Sites in Canada

Media Inquiries

General Inquiries

Please click here to e-mail LANXESS Canada with product inquiries and general requests.

Global Press Releases

2019-04-16

Successfully proven brine treatment

- LANXESS ion exchangers being used for brine purification in chlor-alkali electrolysis

- Lewatit MDS TP 208 protects highly sensitive electrolysis membranes

- Fine beads enhance the brine treatment process

Cologne – A leading producer of chlor-alkali products on the Indian market benefits from the improved efficiency of his chlor-alkali electrolysis by applying the new Lewatit MDS TP 208 as ion exchange resin from LANXESS. The finely dispersed polymer beads reduce the energy input effectively by preventing damage to the ion exchange membranes used for electrolysis and thus extending their lifespan. Consequently, this new generation of finely dispersed resins is being successfully introduced alongside the MonoPlus types.

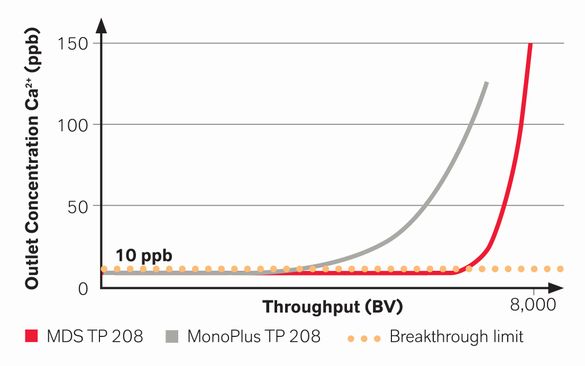

The chemical plant in the south of India has a production capacity of approximately 190 metric kilotons of caustic soda a year requiring a quantity of around 400 cubic meters of sodium chloride brine per hour. The brine used for electrolysis needs to be pretreated to protect the electrolysis membranes from high levels of impurities. Otherwise precipitations can harm the membranes, for example, resulting in a less efficient process. The new Lewatit MDS TP 208 finely dispersed ion exchange resin is being used in one of three filters of one brine treatment line to optimize brine purification. The resin reduces the hardness of the brine from an incoming level of 2 mg/l to below 10 µg/l (Ca2+, Mg2+). The chemical plant also has an effective process for removing barium and strontium levels to a concentration of below 100 µg/l.

The use of the Lewatit MDS TP 208 chelate resin from LANXESS enables effective economic advantages for the plant operator, in particular in terms of significant energy cost savings. Further advantages include a longer lifetime for the membranes and the resin. Additionally reduced quantities of regeneration agents are required and a reduction of wastewater is expected to lower operating costs. The resin type used is capable of achieving longer cycle times, which in turn generates a higher brine treatment throughput. Based on the positive results, the Indian producer decided to switch the other two resin filters of this line to Lewatit MDS TP 208 as well.

Since installation of the resins in 2016, the customer has enhanced the capacity of this brine treatment line by 53 percent in two years. The use of Lewatit MDS TP 208 has increased the throughput from 3,035 BV (bed volumes) to 4,662 BV.

You can find more detailed information about products from the LPT business unit on the website at http://lpt.lanxess.com.

Forward-Looking Statements

This company release contains certain forward-looking statements, including assumptions, opinions, expectations and views of the company or cited from third party sources. Various known and unknown risks, uncertainties and other factors could cause the actual results, financial position, development or performance of LANXESS AG to differ materially from the estimations expressed or implied herein. LANXESS AG does not guarantee that the assumptions underlying such forward-looking statements are free from errors nor does it accept any responsibility for the future accuracy of the opinions expressed in this presentation or the actual occurrence of the forecast developments. No representation or warranty (expressed or implied) is made as to, and no reliance should be placed on, any information, estimates, targets and opinions, contained herein, and no liability whatsoever is accepted as to any errors, omissions or misstatements contained herein, and accordingly, no representative of LANXESS AG or any of its affiliated companies or any of such person's officers, directors or employees accept any liability whatsoever arising directly or indirectly from the use of this document.

LANXESS is a leading specialty chemicals company with sales of EUR 7.2 billion in 2018. The company currently has about 15,400 employees in 33 countries and is represented at 60 production sites worldwide. The core business of LANXESS is the development, manufacturing and marketing of chemical intermediates, additives, specialty chemicals and plastics. LANXESS is listed in the leading sustainability indices Dow Jones Sustainability Index (DJSI World and Europe) and FTSE4Good.

- Gallery