Asia

EMEA

LANXESS Canada Contacts

Contact our Sites in Canada

Media Inquiries

General Inquiries

Please click here to e-mail LANXESS Canada with product inquiries and general requests.

Global Press Releases

2010-03-09

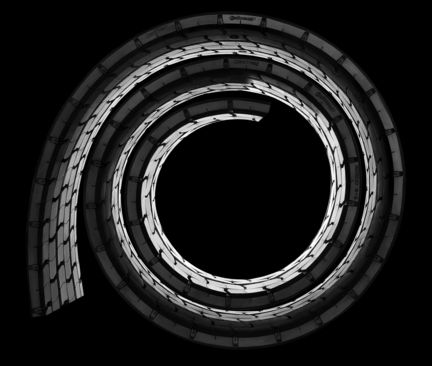

Focus on tire retreading

LANXESS aims to offer ESBR black masterbatch in Brazil

The Performance Butadiene Rubbers (PBR) business unit of specialty chemicals group LANXESS is considering the possibility of manufacturing ESBR-BMB (emulsion styrene-butadiene rubber black masterbatch) in the future in Brazil. Options for doing so at the production sites of Triunfo or Caxias are currently being examined. This step would serve to meet the growing raw material demands of the retread industry, which is especially strongly represented in North and South America. 18 million respectively 9 million truck and bus tires get retread every year in these regions.

“Manufacturing ESBR-BMB in Brazil would ideally supplement our CoBR-BMB production capacities in Orange, Texas. It would enable us to supply these important products to our retreading customers in America from one source and region,” says Dr. Joachim Grub, head of the PBR business unit, adding: “Retreading tires saves resources by enabling tire carcasses to be used several times. The use of LANXESS rubber can also lower the rolling resistance of the newly treaded tires, thus cutting fuel consumption.”

BMB products are easier to process during compounding since there is no longer any need for the compounder to mix ESBR with carbon black and oil. In addition, wet mixing during BMB manufacture leads to better dispersion of the filler particles, which can have a positive effect on the properties of the end product.

“In addition to the established markets in America and Europe along with those in the Middle East and Africa, we see particularly good growth potential in China and India,” remarks Christoph Kalla, head of Marketing and R&D in the PBR business unit. “In these countries, the retread sector has not yet been able to keep pace with the enormous increase in demand for tires. An improved quality of the radial tires produced should enable the retread industry to catch up.”

This examination of possible options is one of a number of activities by LANXESS designed to offer ESBR customers higher-quality products and services. For example, the entire range of oil-extended ESBR grades has been offered with "safe" processing oils since January 1, 2010. In addition, from April 1, 2010 only metal boxes will be used for the primary packaging to offer customers better protection against contamination than is possible with wood or cardboard.

Forward-Looking Statements

This news release contains forward-looking statements based on current assumptions and forecasts made by LANXESS AG management. Various known and unknown risks, uncertainties and other factors could lead to material differences between the actual future results, financial situation, development or performance of the company and the estimates given here. The company assumes no liability whatsoever to update these forward-looking statements or to conform them to future events or developments.

LANXESS is a leading specialty chemicals company with sales of EUR 6.58 billion in 2008 and currently around 14,600 employees in 23 countries. The company is represented at 43 production sites worldwide. The core business of LANXESS is the development, manufacturing and marketing of plastics, rubber, intermediates and specialty chemicals.

Information for editors:

All LANXESS news releases and their accompanying photos can be found at http://corporate.lanxess.de/en/media/press-releases/. Recent photos of the Board of Management and other LANXESS image material are available at http://fotos.lanxess.de/index_en.html. The latest TV footage, audiofiles and podcasts can be found at http://corporate.lanxess.com/en/media/audio-video/.

You can find further information concerning LANXESS chemistry in our WebMagazine at http://webmagazine.lanxess.com.

- Gallery