Asia

EMEA

LANXESS Canada Contacts

Contact our Sites in Canada

Media Inquiries

General Inquiries

Please click here to e-mail LANXESS Canada with product inquiries and general requests.

Global Press Releases

2010-03-17

New PBT blends for exterior truck cab components

Polybutylene terephthalate (PBT) blends can be used in many different ways in the production of paneling/moldings and add-on body parts for truck cabs. Examples include fenders, wind deflectors, A-pillars, access steps and radiator grilles. One existing series application is the bumper of the Eurocargo truck from IVECO, which is made from the glass fiber-reinforced PBT+PET blend Pocan TS3220. The success of this material has now resulted in LANXESS adding Pocan A3131, C3230 XF and T3150 XF to its portfolio of PBT blends for exterior truck components. “The three materials have each been optimized with specific strengths in mind, such as good coatability, minimal distortion and excellent stiffness. They also offer the usual advantages of PBT blends,” explains Jürgen Horstmann, Key Account Manager for the truck industry in the Semi-Crystalline Products business unit.

Coating flexibility

Pocan A3131 is a PBT+ASA blend reinforced with 30 percent glass fibers. “This material has been optimized to minimize distortion, produces smooth surfaces that are easy to coat and boasts excellent flowability, which also makes it ideal for thin-walled components with finely structured geometries,” states Dr. Ulrich Plutowski, Product Developer for Pocan. One special feature of the material is its high heat resistance (Vicat 175 °C, ISO 306), which creates a larger process window for coating such components. Potential applications include large, low-distortion components such as wind deflectors and door extensions.

Isotropic shrinkage

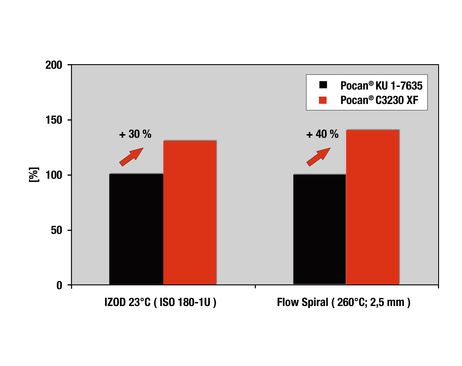

The key strength of Pocan C3230 XF is its minimal distortion. The PBT+PC blend filled with 30 percent glass fibers demonstrates virtually isotropic shrinkage behavior in the component. The material’s flowability and toughness have also been improved. This is unusual because these two properties normally counteract each other. The material has 40 percent higher flowability and is 30 percent tougher than the standard PBT+PC blend Pocan KU 1-7635. It also yields excellent surfaces and is ideal for components that need to have very accurate dimensions – such as lamp housings and large panels/trim.

Extremely stiff

Pocan T3150 XF is the material of choice for functional components and for components intended for structural reinforcement that must both demonstrate excellent stiffness and strength. This extremely tough, highly reinforced PBT+PET blend with 55 percent glass fibers has a very high elasticity modulus of 18,500 MPa (at room temperature) that is not affected by the level of humidity. It has a Charpy impact strength (ISO 179-1eU) of 55 kJ/m² at 23 °C. “This low-distortion material with a high elasticity modulus could be used instead of die-cast aluminum in many applications – such as handles, mirror arms and steps. The components can also be realized as plastic-metal composites,” says Plutowski. A further unusual feature is the blend’s good weather resistance, despite its high glass-fiber content.

Service along the entire component development chain

LANXESS helps manufacturers of exterior truck components made from PBT blends all the way along the development chain. In addition to mold flow calculations and CAE simulations, it also performs drop, vibration, dynamic/static stress tests and accelerated weathering tests. “Feasibility studies on substituting PBT for metals or SMCs blends are a further key aspect of our service,” notes Horstmann. Exterior applications for plastics are not the only focus of key account management for the truck industry, however. Applications for the vehicle interior and engine compartment – such as dashboard trim panels, oil pans, oil filter covers, cylinder head covers and coolant pipes – are also important.

Forward-Looking Statements

This news release contains forward-looking statements based on current assumptions and forecasts made by LANXESS AG management. Various known and unknown risks, uncertainties and other factors could lead to material differences between the actual future results, financial situation, development or performance of the company and the estimates given here. The company assumes no liability whatsoever to update these forward-looking statements or to conform them to future events or developments.

Information for editors:

All LANXESS news releases and their accompanying photos can be found at http://corporate.lanxess.de/en/media/press-releases/. Recent photos of the Board of Management and other LANXESS image material are available at http://fotos.lanxess.de/index_en.html. The latest TV footage, audiofiles and podcasts can be found at http://corporate.lanxess.com/en/media/audio-video/.

You can find further information concerning LANXESS chemistry in our WebMagazine at http://webmagazine.lanxess.com.

LANXESS is a leading specialty chemicals company with sales of EUR 5.06 billion in 2009 and currently around 14,300 employees in 23 countries. The company is represented at 43 production sites worldwide. The core business of LANXESS is the development, manufacturing and marketing of plastics, rubber, intermediates and specialty chemicals.

- Gallery